Cast Concrete Retaining Wall Blocks: 2025 Ultimate Guide

Why Cast Concrete Retaining Wall Blocks Transform Sloped Landscapes

Cast concrete retaining wall blocks are precast modular units designed to manage slopes, prevent soil erosion, and create usable outdoor spaces. For homeowners in the Greater Boston area struggling with sloped yards, these blocks offer a stable, long-term solution. They arrive on-site manufactured to strict standards, unlike poured concrete or natural stone.

These engineered blocks come in two main types:

- Large-format wet-cast blocks: Massive one-ton units with natural stone textures, ideal for tall gravity walls.

- Segmental Retaining Wall (SRW) blocks: Smaller, dry-cast units that interlock without mortar, offering flexibility for curves and terraced designs.

Their effectiveness lies in physics. Gravity walls use the sheer weight of large-format blocks to resist soil pressure. For taller walls, reinforced systems use geogrid—a synthetic mesh extending into the soil—to create a stable, unified mass that prevents failure.

Precast blocks are practical due to their built-in engineering. Features like interlocking lips, setback angles, and hollow cores for drainage are molded into each unit. This ensures faster installation and robust performance against New England’s freeze-thaw cycles, making them a smart choice for any property.

A Guide to the Different Types of Precast Concrete Blocks

Not all cast concrete retaining wall blocks are created equal. The main distinctions are manufacturing process (wet-cast vs. dry-cast) and size, which affect everything from strength and texture to installation method.

Large-Format Wet-Cast Blocks

Think of these as giant, engineered Lego blocks, often weighing a ton or more. The “wet-cast” process creates incredibly dense, strong units. Manufacturers use molds from actual stone to produce deep, natural textures like Cobblestone, Ledgestone, or Stack Stone, giving you the beauty of natural stone with engineered precision.

Their massive weight is their superpower. These blocks can build gravity walls reaching 12 feet or more without geogrid reinforcement, holding back earth through sheer mass. For a property in Everett or Malden with a significant grade change, this means faster installation and fewer complications, as one block can cover over five square feet of wall face.

Segmental Retaining Wall (SRW) Blocks

SRW blocks are the modular, adaptable workhorses of retaining walls. Made through a “dry-cast” process, they are designed to be stacked without mortar, relying on their weight, interlocking features, and geogrid reinforcement.

The hollow-core design is a key feature. When filled with wall rock, these cores provide excellent internal drainage, which is critical during New England’s freeze-thaw cycles. The hollow cores also make the blocks lighter and easier to handle, which is ideal when property access in Lynnfield or Revere is tight.

For taller walls, SRW blocks work with geogrid reinforcement. This synthetic mesh extends into the soil, creating a Mechanically Stabilized Earth (MSE) structure. The geogrid and soil work together as one stable mass, allowing SRW walls to reach impressive heights safely.

SRW blocks offer best versatility. Their modular nature makes it easy to create curves, add steps, or build multiple tiers. This design flexibility allows for complex, custom projects without sacrificing engineering integrity.

The Engineering Principles of Cast Concrete Retaining Wall Blocks

A professionally designed wall lasts for decades because it’s an engineered structure fighting against thousands of pounds of soil pressure. Understanding the principles behind cast concrete retaining wall blocks shows why they are so effective.

Gravity Wall Mechanics

A gravity wall uses pure mass to resist the push of soil. The immense weight of large-format wet-cast blocks, combined with a setback (where each layer sits slightly behind the one below), creates an incredibly stable structure. Many systems also feature interlocking connections, ensuring the blocks work as a single, solid unit. This approach allows some walls to reach heights of 12 feet or more without extra reinforcement.

Reinforced Wall Principles

When gravity isn’t enough for taller walls or challenging soil, engineers use geogrid reinforcement. This high-strength synthetic mesh is laid between block courses and extends back into the soil. The geogrid and soil create a unified, stable mass known as Mechanically Stabilized Earth (MSE)—the same technology used in major highway projects. This system requires blocks with high structural integrity, typically with a compressive strength of at least 3,000 PSI and adherence to industry standards like ASTM 1372.

Resisting Pressure: The Role of Drainage and Site Conditions

The biggest threat to a retaining wall is not soil, but the water trapped behind it. Hydrostatic pressure, especially during New England’s freeze-thaw cycles, can cause walls to bow or fail. The soil type on your property—water-retaining clay or free-draining sand—also dictates the design.

Proper drainage is non-negotiable. It involves a perforated drain pipe at the base, surrounded by clean gravel backfill to create a path for water to escape. A layer of geotextile fabric separates the gravel from the native soil, preventing clogs. Finally, proper compaction of the backfill material in 8-inch layers is critical to remove air voids and ensure the entire system works as one stable structure. These details are why our professional retaining wall installation process is so thorough.

Quality Assurance for Cast Concrete Retaining Wall Blocks

Precast blocks offer quality that can’t be replicated on-site. Manufactured in controlled facilities, they have consistent strength, precise dimensions, and uniform interlocking features. Many are made with air-entrained concrete, which includes microscopic air bubbles to absorb the stress of freezing water, enhancing durability. This commitment to quality control, verified through rigorous testing against standards from organizations like the National Concrete Masonry Association, ensures the components are engineered to last for generations.

Applications, Aesthetics, and Customization

Cast concrete retaining wall blocks are more than just functional; they are opportunities to create practical and beautiful changes on your property.

Typical Applications for Cast Concrete Retaining Wall Blocks

In communities like Saugus and Everett, these blocks solve common landscape challenges. They turn sloped, unusable yards into level areas perfect for:

- Terraced gardens that are beautiful and easy to maintain.

- Raised patios that define outdoor living spaces.

- Driveway support on graded properties.

- Integrated seating that combines function with style.

Commercial projects in Malden and Lynnfield use these blocks for stabilizing building sites, creating parking areas, and supporting roadways. They are also excellent for water management, helping to control stormwater runoff and prevent erosion.

Aesthetic Appeal and Customization Possibilities

Modern cast concrete retaining wall blocks offer a vast range of aesthetic options to complement any home. The surface texture can mimic natural stone, with popular choices including the rounded look of cobblestone, the flat planes of ledgestone, or a clean, smooth finish for a contemporary feel.

Integral colors are mixed directly into the concrete, offering earthy browns, tans, bold charcoals, and subtle grays that won’t fade. This allows the wall to blend with or accent your home’s exterior.

The modular nature of the blocks allows for immense design flexibility. You can create graceful curves that follow your landscape’s contours or sharp corners to define an outdoor room. Steps and stairs can be integrated directly into the wall for seamless transitions between levels. Features like built-in planters or lighting niches can also be added, changing a simple wall into a multi-functional landscape element.

Planning Your Project: Installation and Cost Factors

Building a retaining wall is a significant project requiring careful planning, professional expertise, and a realistic budget. Understanding the installation process and cost factors is key.

Installation Considerations for Cast Concrete Retaining Wall Blocks

Properly installing cast concrete retaining wall blocks is a complex job that demands precision and experience. While a small, decorative wall under 2 feet might be a DIY project, any structural wall requires a professional.

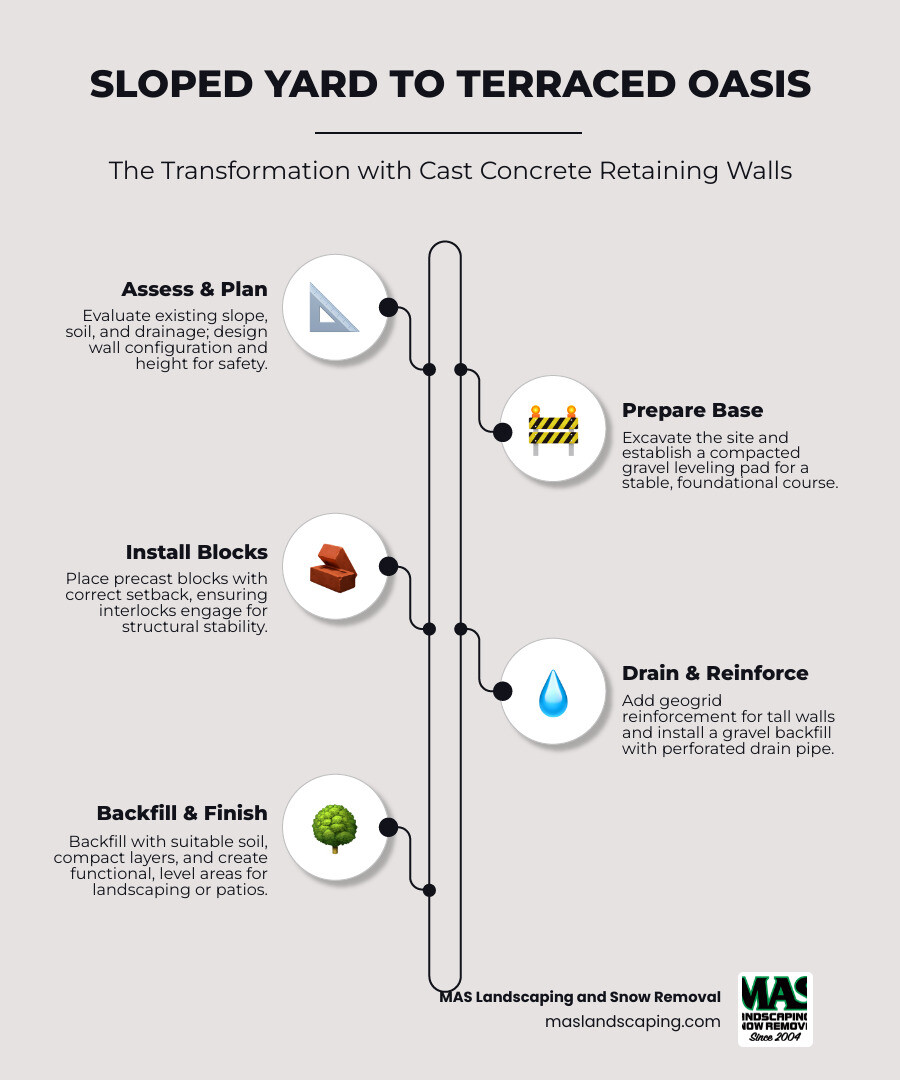

The key stages of a professional installation include:

- Site Preparation and Foundation: This involves excavating to the correct depth and creating a perfectly level, compacted gravel base. The first course of blocks is partially buried on this foundation for stability.

- Building, Backfilling, and Compaction: As courses are added with a slight setback, the area behind the wall is filled with drainage aggregate and soil. This backfill must be compacted in thin layers to prevent future settling.

- Drainage and Reinforcement: A perforated drain pipe is installed at the base to channel water away, which is essential in Massachusetts. Taller walls require geogrid reinforcement layered within the backfill to create a stable, unified structure.

- Finishing: Capstones are added to the top for a polished look and to protect the wall from water infiltration.

Cutting corners on any of these steps can lead to wall failure. That’s why professional installation, which you can learn more about in our professional retaining wall installation process, is a crucial investment.

Understanding the Costs of Cast Concrete Retaining Wall Blocks

Getting a straight answer on cost is difficult because every project is unique. Please note that any pricing mentioned here represents average costs based on internet data and not actual costs for MAS Landscaping. We provide personalized quotes based on your specific project.

Online, you may find individual cast concrete retaining wall blocks ranging from $25 to over $95 per block, with larger, decorative blocks at the higher end. A complete project in the Greater Boston area could range from $5,000 for a small wall to $30,000 or more. Large or complex projects can exceed $100,000.

Key factors that drive the final cost include:

- Wall size (height and length)

- Site accessibility for equipment

- Soil conditions (rocky or clay soils increase costs)

- Block type and aesthetic choices

- Reinforcement needs (geogrid for taller walls)

- Permitting and engineering fees (often required for walls over 4 feet)

Professional installation is a significant part of the cost, but it provides peace of mind, ensuring your wall is safe, functional, and built to last.

| Feature | Precast Concrete Blocks (SRW) | Precast Concrete Blocks (Large-Format) |

|---|---|---|

| Durability | Very High (50-100+ years with proper installation) | Very High (50-100+ years with proper installation) |

| Cost | Mid-range to High (depends on block size, texture, height) | High (due to block size, weight, and often specialized installation) |

| Installation Speed | Moderate (faster than poured, slower than large-format for same height) | Fast (massive blocks cover large area quickly) |

| Aesthetics | Highly customizable with various textures, colors, and layouts | Highly customizable with deep natural stone textures, diverse colors |

Frequently Asked Questions about Concrete Block Walls

Homeowners in Saugus, Lynnfield, and Revere often have similar questions when planning a retaining wall. Here are answers to the most common ones.

How long do cast concrete retaining walls last?

A properly designed and installed wall built with cast concrete retaining wall blocks is a permanent landscape feature, expected to last 50 to 100 years or more. Its longevity comes from the combination of high-strength concrete, interlocking designs, and, most importantly, a proper drainage system. By preventing water buildup and the destructive force of New England’s freeze-thaw cycles, a well-built wall will stand strong for decades.

Do I need a permit to build a retaining wall in Massachusetts?

Usually, yes. In Massachusetts, walls over 4 feet in height generally require a building permit and a design stamped by a professional engineer. This is a critical safety measure. However, regulations can vary by town, so what applies in Saugus might differ in Everett or Malden. It is essential to check with your local building department early in the planning process to avoid costly delays and ensure compliance.

Can I build a concrete block retaining wall myself?

For a small, decorative garden wall under 2 feet, a DIY approach might be feasible if you are handy. However, for any wall holding back a significant amount of soil, professional installation is essential for safety, stability, and durability.

Building a structural wall involves complex factors like soil mechanics, hydrostatic pressure, proper foundation work, and specialized compaction equipment. A failed wall can cause serious property damage and create a dangerous liability. The team at MAS Landscaping and Snow Removal has the local expertise, equipment, and experience to build walls in the Saugus area that are safe and built to last.

Conclusion

If a challenging slope is limiting your property’s potential, cast concrete retaining wall blocks offer a durable, beautiful, and proven solution. From massive wet-cast blocks to versatile segmental systems, these products combine engineered strength with impressive aesthetic flexibility.

The key to open uping their 50-100 year lifespan is professional installation. Proper drainage, compaction, and an understanding of local soil conditions are what separate a wall that lasts for generations from one that fails. It’s not just about stacking blocks; it’s about building a permanent landscape solution.

For homeowners in Saugus, MA, and surrounding communities like Everett, Lynnfield, and Malden, MAS Landscaping and Snow Removal offers the local expertise to do the job right. We understand New England’s climate and know how to transform unusable slopes into stunning, functional spaces like patios and terraced gardens. Let us help you reclaim your yard and turn your vision into a reality.

Explore our hardscaping services to start planning your retaining wall project today!