Why Understanding Walkway Construction Matters for Your Home

A walkway builder designs and installs durable, attractive pathways that connect your outdoor spaces. Whether you’re considering a DIY project or hiring a professional, understanding the construction process helps you make informed decisions about materials, costs, and design.

Walkway Project Overview:

- Professionals handle all aspects, from site prep to material selection.

- DIY can save money but requires the right tools, knowledge, and physical labor.

- Key factors include drainage, material choice, and proper base preparation.

- Timelines range from a few weekends for DIY to 1-2 weeks for professional jobs.

- Costs vary based on materials, from budget-friendly concrete to premium natural stone.

Here’s something that surprises most homeowners: the walkway you see is only about 20% of the actual project. As one experienced DIYer shared, “Laying that walkway was one of our toughest DIY projects ever—there’s a reason crews are big and burly!”

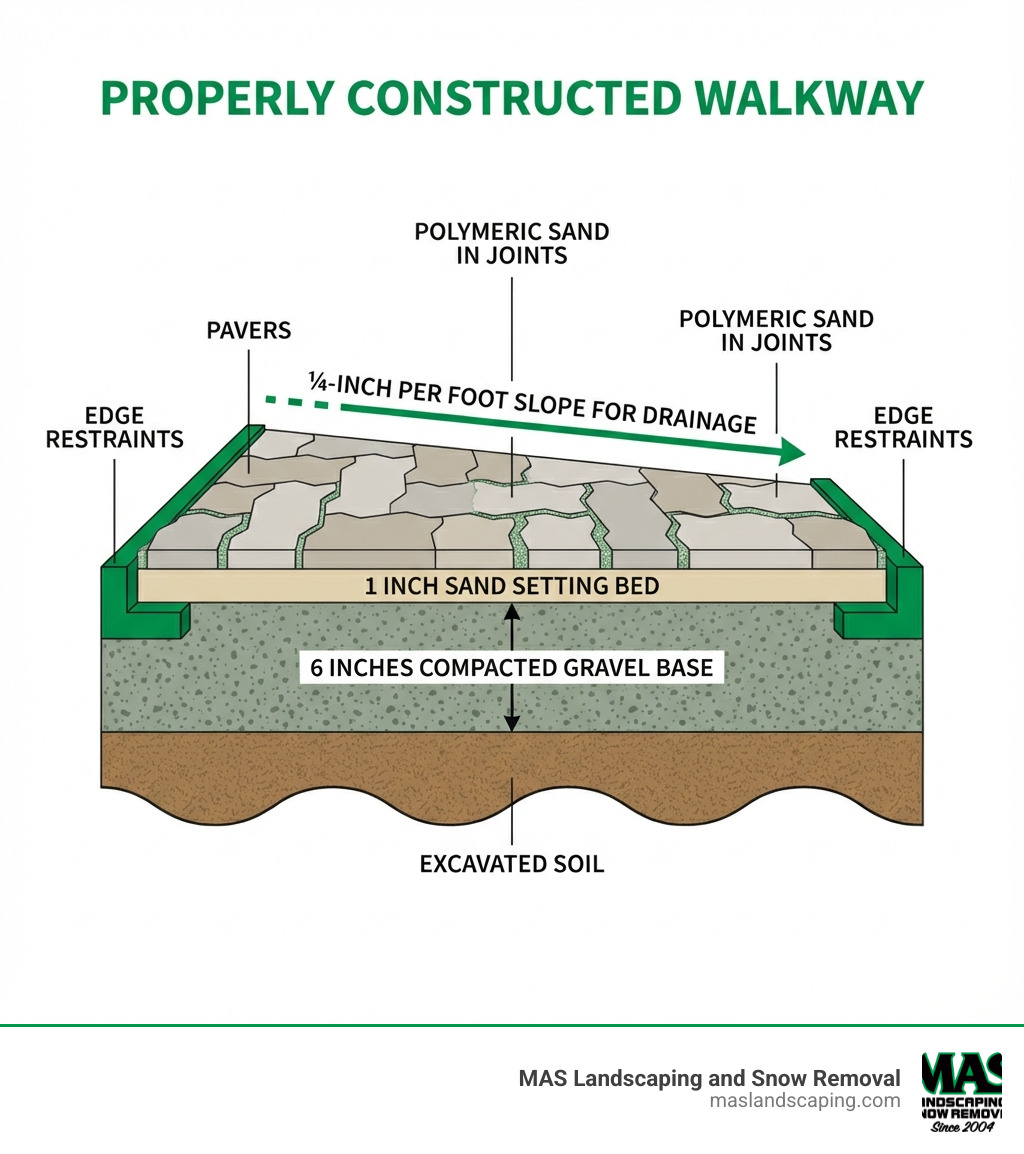

The real work happens below the surface. Proper base preparation determines whether your walkway lasts for decades or fails within a few years.

A well-designed walkway guides visitors, defines outdoor spaces, and significantly boosts curb appeal, adding measurable value to your home. Building one requires careful planning and attention to detail, especially regarding excavation depth (6-12 inches), drainage slope (¼ inch per foot), base compaction, and jointing materials.

This guide covers every step, from design to finishing touches, helping you choose the right materials, avoid common mistakes, and decide when to call a professional.

Walkway builder glossary:

Planning & Design: Your Blueprint for a Beautiful Walkway

A successful walkway begins with careful planning. This phase defines the path’s function and aesthetic, whether it’s a grand entrance, a winding garden path, or a practical route. A well-designed walkway is a vital landscape element that improves curb appeal, sets a welcoming tone, and can significantly increase home value.

One of the first decisions is width. A minimum of 36 inches is needed for one person, but 48 inches is more comfortable for two people or for carrying items. For wheelchair or stroller accessibility, 60 inches is the ideal width.

For more inspiration on how thoughtful design can transform your outdoor areas, explore our resources on landscape design and hardscape design services.

Choosing Your Materials

The choice of material impacts the look, durability, maintenance, and cost of your walkway. Consider the path’s intended use, your home’s style, and the local Massachusetts climate when selecting materials.

Here’s a look at popular options:

- Pavers: Versatile and durable, paver walkways can last 50-100+ years. They are easily repaired by replacing single units and come in endless colors, shapes, and textures.

- Natural Stone: Flagstone, bluestone, or granite offer a timeless, organic look. Each stone is unique, but softer stones like limestone aren’t ideal for high-traffic areas. Sealing is often required to prevent staining.

- Poured Concrete: A sleek, modern, and often less expensive option. However, cracks can require costly repairs or full replacement. Regular sealing is crucial to maintain its appearance.

Climate and Soil: In areas like Saugus, Everett, and Lynnfield, MA, materials must withstand freeze-thaw cycles. Pavers handle this well, while improperly installed concrete can crack. Soil type is also critical; clay soil expands and shrinks, while sandy soil can wash out. A professional walkway builder engineers the base to handle these local conditions, ensuring longevity.

Designing the Layout and Pattern

With your material chosen, it’s time to design the layout. Use a garden hose to visualize and adjust curves, and use stakes and string for precise straight lines. The 3-4-5 triangle method helps ensure perfect 90-degree corners.

The paver pattern affects both appearance and durability:

- Running Bond: A classic pattern with offset joints, excellent for guiding the eye along curved paths.

- Herringbone: An interlocking pattern that is extremely durable and resists shifting, ideal for high-traffic areas.

- Basketweave: Alternating pairs of pavers create a charming, woven look.

The pattern should harmonize with your home’s style and landscape, turning a simple path into a design feature.

Groundwork: How to Prepare and Build a Base That Lasts

A strong, stable base is the single most important factor for a long-lasting walkway. Skimping on this step is a recipe for failure.

Site Preparation

Meticulous site preparation is the first step. Mark the path and always call 811 at least 48 hours before digging to have underground utilities marked for safety.

Next, excavate 6-12 inches below the finished grade. This depth accommodates the base, sand bed, and pavers. The exact depth depends on soil type and expected foot traffic.

Grading for Drainage

Proper drainage is critical to prevent water damage. Ensure every surface slopes away from your home’s foundation at a rate of ¼ inch per foot. This subtle slope prevents pooling water, keeping the walkway safe and dry.

Building the Base

With the site prepared, build the base in layers:

- Geotextile Fabric: On unstable soil, lay geotextile fabric first. It separates the base material from the native soil, improving stability.

- Compacted Gravel Layers: Install a minimum of 6 inches of gravel, compacting it in 3-inch layers (lifts). This prevents uneven settling.

- Sand Setting Bed: Spread a uniform 1-inch layer of coarse sand over the gravel. This cushions the pavers and allows for fine-tuning the level.

- Edge Restraints: Install hidden plastic or metal restraints around the perimeter. They are essential for preventing pavers from spreading apart over time.

For larger projects or complex grading, our team can help. Learn more about our landscape grading services and Bobcat services.

The Critical Step of Compaction

Compaction is the most critical step and the number one reason DIY walkways fail. It involves compressing the base materials to create a dense, stable foundation that prevents settling and trip hazards.

While a hand tamper works for small jobs, a plate compactor is essential for most projects. A rental typically costs $40-$60 per day and is worth every penny for ensuring a solid base.

You can find more information on plate compactor rental from various equipment providers.

Common Construction Mistakes to Avoid

Avoid these common pitfalls to ensure your walkway lasts for decades:

- Insufficient Base Depth: A thin gravel base will lead to settling and an uneven surface.

- Poor Compaction: Failing to use a plate compactor properly leaves air pockets that cause dips and shifts.

- Ignoring Drainage Slope: Forgetting the ¼-inch per foot slope causes water to pool, undermining the base.

- Skipping Edge Restraints: Without them, pavers will migrate outwards, ruining the walkway’s stability and lines.

- Using the Wrong Sand: Use coarse bedding sand for the setting bed and polymeric sand for joints; other types will fail.

The Art of Laying: From Pavers to Finishing Touches

With the base prepared, you’re ready to lay the pavers. This stage requires patience and precision for a professional finish.

Laying Method

Start laying pavers from a fixed edge, like a foundation or patio, to ensure a straight reference line. Gently place each paver onto the sand bed—don’t drag it. Use a rubber mallet to tap pavers into place, keeping them level with consistent 1/8-inch gaps.

Cutting Pavers

Some pavers will need cutting to fit edges and curves. A rented masonry saw provides the cleanest cuts, while a hammer and chisel can work for smaller adjustments. Always wear safety gear, including eye and hearing protection, when cutting.

Jointing with Polymeric Sand

Filling the joints with polymeric sand is a crucial finishing step. This special sand contains binders that harden when wet, creating a flexible but solid joint that locks pavers together.

Benefits of polymeric sand include:

- Weed Prevention: Blocks up to 98% of weed growth in joints.

- Stabilization: Locks pavers in place, preventing shifting.

- Insect Deterrent: Deters ants from nesting between pavers.

To apply, sweep the sand into the joints, compact the pavers to settle the sand, and sweep in more until full. Finally, lightly mist with water to activate the binders.

Sealing for Protection

Sealing pavers every 3-5 years is recommended to protect their color from UV fading, prevent stains, and further harden the joint sand. While not always required for durability, it improves the look and longevity.

For more detailed guides, check out our pages on paver patio installation and brick walkway ideas.

Eco-Friendly Walkway Options

Consider sustainable options for your project:

- Permeable Pavers: These allow rainwater to filter into the ground, managing stormwater runoff. They may cost 20-30% more upfront but offer long-term environmental benefits.

- Recycled/Reclaimed Materials: Pavers made from recycled concrete or reclaimed brick reduce waste and add unique character.

- Gravel Joints: Using gravel in joints instead of sand offers a rustic look and natural drainage.

Improvements, Maintenance, and Costing Your Project

Thoughtful improvements and regular maintenance will keep your walkway beautiful and functional for decades.

Landscape Lighting

Landscape lighting is an impactful improvement. Low-voltage LED or solar path lights increase safety at night and create a captivating ambiance, changing your walkway into a nighttime feature.

For expert lighting design and installation, consider our landscape lighting install services.

Softening Edges with Plants

Plantings along the edges soften the walkway’s hard lines, blending it into the landscape. Drought-tolerant groundcovers, shrubs, or perennials add color, texture, and fragrance.

Walkway Maintenance

Regular maintenance extends the life and beauty of your walkway. Needs vary by material:

| Material Type | Annual Maintenance Tasks | Long-Term Care | Average Lifespan |

|---|---|---|---|

| Pavers | Sweep regularly, annual deep clean, check for weeds. Clear leaves promptly. Use plastic shovels for snow removal to avoid rust. | Re-sand joints with polymeric sand every 3-5 years. Seal every 3-5 years. | 50-100+ years |

| Natural Stone | Sweep regularly, annual deep clean, check mortar joints (if applicable). Clear leaves to prevent staining. | Re-point mortar joints as needed. Re-seal as recommended by stone type (e.g., every 1-3 years for porous stone). | 50-100+ years |

| Poured Concrete | Sweep regularly, annual deep clean. Clear leaves to prevent discoloration. Use magnesium chloride for ice melt, avoid rock salt. | Re-seal every 1-3 years to protect against stains and weather. | 25-50 years (can crack and require replacement) |

For comprehensive care, our landscape maintenance services can help keep your entire outdoor space pristine.

Budgeting for Your Walkway

Understanding the costs is crucial. Based on general internet data, DIY material costs can range from $2.50 to $18 per square foot, with premium materials pushing that to $50+ per square foot.

Professional installation adds labor costs, which can be 45% or more of the material price. This covers expertise, equipment, and a quality guarantee. Project complexity, site access, and grading issues will also influence the final cost. When ordering materials, always get about 10% extra to account for cuts, breakage, and future repairs.

DIY vs. Hiring a Professional Walkway Builder

Deciding between a DIY project and hiring a professional walkway builder depends on your skills, time, budget, and project complexity. For homeowners in Everett, Malden, or Melrose, MA, DIY offers cost savings and satisfaction but involves heavy labor and the risk of costly errors, especially with base preparation.

Hiring a professional walkway builder like MAS Landscaping ensures expertise, quality, and efficiency. A pro handles complex designs, ensures proper drainage, and selects the right materials for our climate. The investment provides peace of mind, a warranty, and a finished product that improves home value. For more details, see our hardscaping contractor ultimate guide.

When to DIY

A DIY approach is suitable if:

- The project is a simple, straight, and small path.

- You have the right tools (or can rent them), including a plate compactor and masonry saw.

- You are physically capable and have the time for a demanding project.

Questions to Ask a Potential Walkway Builder

When hiring a professional, ask these crucial questions:

- Can I see your portfolio and references?

- Are you licensed and insured?

- Do you offer a workmanship warranty?

- Can I get a detailed, itemized quote?

- What is the estimated project timeline?

- What is your crew’s experience level?

Why a Professional Walkway Builder is a Smart Investment

A professional is the smartest investment for:

- Complex Designs: Intricate curves, steps, or retaining walls require technical skill.

- Large-Scale Projects: Extensive walkways need specialized equipment and efficient management.

- Grading or Drainage Issues: Sloped properties need expert engineering for a stable, dry walkway.

- Longevity and Home Value: A professionally installed walkway is built to last, providing superior durability and boosting curb appeal.

For reliable professionals in the Saugus, Everett, Malden, Medford, Lynnfield, Revere, Chelsea, or Melrose, MA areas, explore our services for companies that install pavers near me.

Frequently Asked Questions about Walkway Construction

Here are answers to common questions about walkway construction.

How wide should a walkway be?

A minimum of 36 inches is recommended for a single person. For more comfort or for two people, 48 inches is ideal. For ADA accessibility (wheelchairs, strollers), walkways should be 60 inches wide. Wider paths generally feel more spacious and welcoming.

How do I prevent weeds from growing in my paver walkway?

The best defense is a properly installed base and using high-quality polymeric sand in the joints. This sand hardens to create a barrier that blocks most weed growth. Regular sweeping and applying a sealant every few years will also help prevent weeds.

How much does a professionally installed walkway cost?

Based on general online data, material costs can range from $2.50 to over $50 per square foot. Professional installation adds a labor cost, often 45% or more of the material price. The final cost depends on project complexity, size, site conditions, and location. For an accurate quote for your Massachusetts project, it’s best to consult a local walkway builder.

Conclusion

Building a durable walkway is a rewarding project that improves your home’s curb appeal, function, and value. This guide has covered the essential steps, from planning and base preparation to laying materials and finishing touches.

A well-built walkway is an investment that lasts for decades. While DIY is an option for simple projects, the expertise of a professional walkway builder is invaluable for complex designs, large installations, or properties with drainage challenges. A professional ensures proper construction and a flawless result that withstands the Massachusetts climate.

For homeowners in the Saugus, Everett, Lynnfield, Malden, Medford, Melrose, Revere, or Chelsea, MA areas, MAS Landscaping offers expert walkway design and installation. Our team creates beautiful, functional outdoor spaces for you to enjoy for years.

Get a professional consultation from a trusted walkway contractor to discuss your vision and build your project to perfection.