Why Building a Cement Retaining Wall Is Essential for Your Property

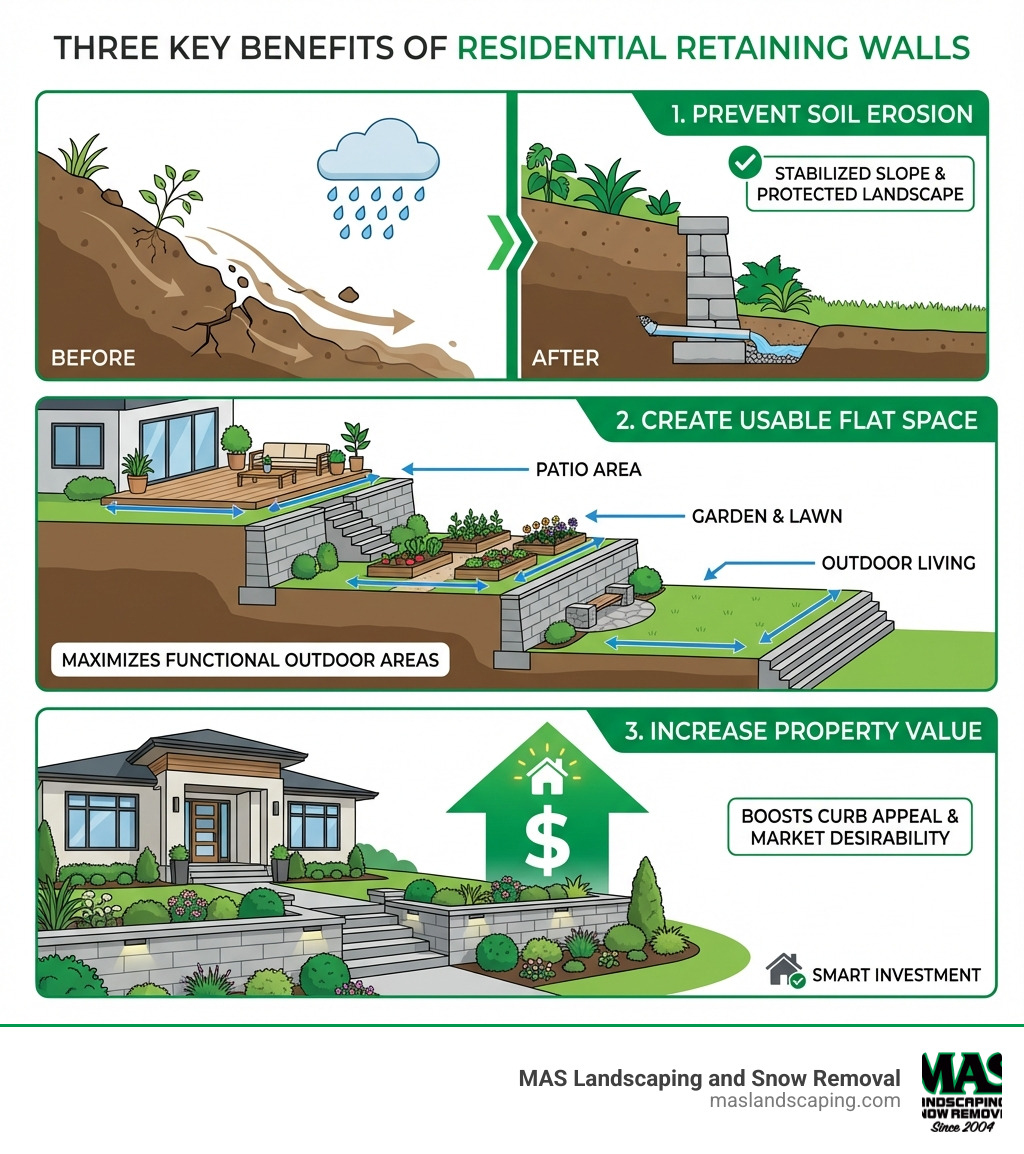

A cement retaining wall is a durable structure designed to hold back soil and manage elevation changes on your property. Whether you’re dealing with a sloped yard, soil erosion, or simply want to create usable outdoor space, a properly built retaining wall is the solution.

Quick Answer: What You Need to Know About Cement Retaining Walls

- Purpose: Prevents soil erosion and creates level, functional spaces

- Main Types: Poured-in-place concrete (custom, high-strength) or concrete blocks (faster, DIY-friendly)

- Key Components: Footing, wall stem, drainage system, backfill, and cap

- Average Lifespan: Over 50 years when properly constructed

- Cost Range: $15-$150 per square foot depending on type and complexity

- Permit Required: Usually yes, for walls over 3-4 feet tall

Building a retaining wall isn’t just about stacking blocks or pouring concrete. It’s about creating a complete system that manages thousands of pounds of earth pressure and water force. One of the principal causes of retaining wall failure is the additional hydrostatic load from water buildup behind the wall, which is why proper drainage design is absolutely critical.

For homeowners in the Greater Boston area, retaining walls solve real problems. They transform unusable sloped yards into beautiful patios and gardens. They protect your property from washouts during New England’s harsh weather. And they can significantly boost your home’s curb appeal and market value.

The global concrete retaining wall market was valued at $1.2 billion in 2022 and is projected to reach $1.9 billion by 2030—a clear sign that more property owners are finding these benefits.

In this guide, we’ll walk you through everything you need to know about building a cement retaining wall that lasts. You’ll learn about the critical components that make a wall stable, the different types available, and a step-by-step construction process. Whether you’re planning a DIY project or hiring professionals, understanding these fundamentals will help ensure your wall stands strong for decades.

Key cement retaining wall vocabulary:

- cast concrete retaining wall blocks

- precast concrete garden walls

- precast concrete retaining wall panels

Understanding the Anatomy of a Retaining Wall

A successful cement retaining wall isn’t just a barrier; it’s a carefully engineered system designed to manage the immense pressure exerted by soil and water. Think of it as a carefully constructed shield protecting your landscape from the relentless forces of nature. When we approach a retaining wall project, we’re considering far more than just the visible face. We’re thinking about the hidden components that ensure its stability and longevity.

Primary Components and Their Functions

Let’s break down the essential parts of a cement retaining wall and what each contributes to the overall structure:

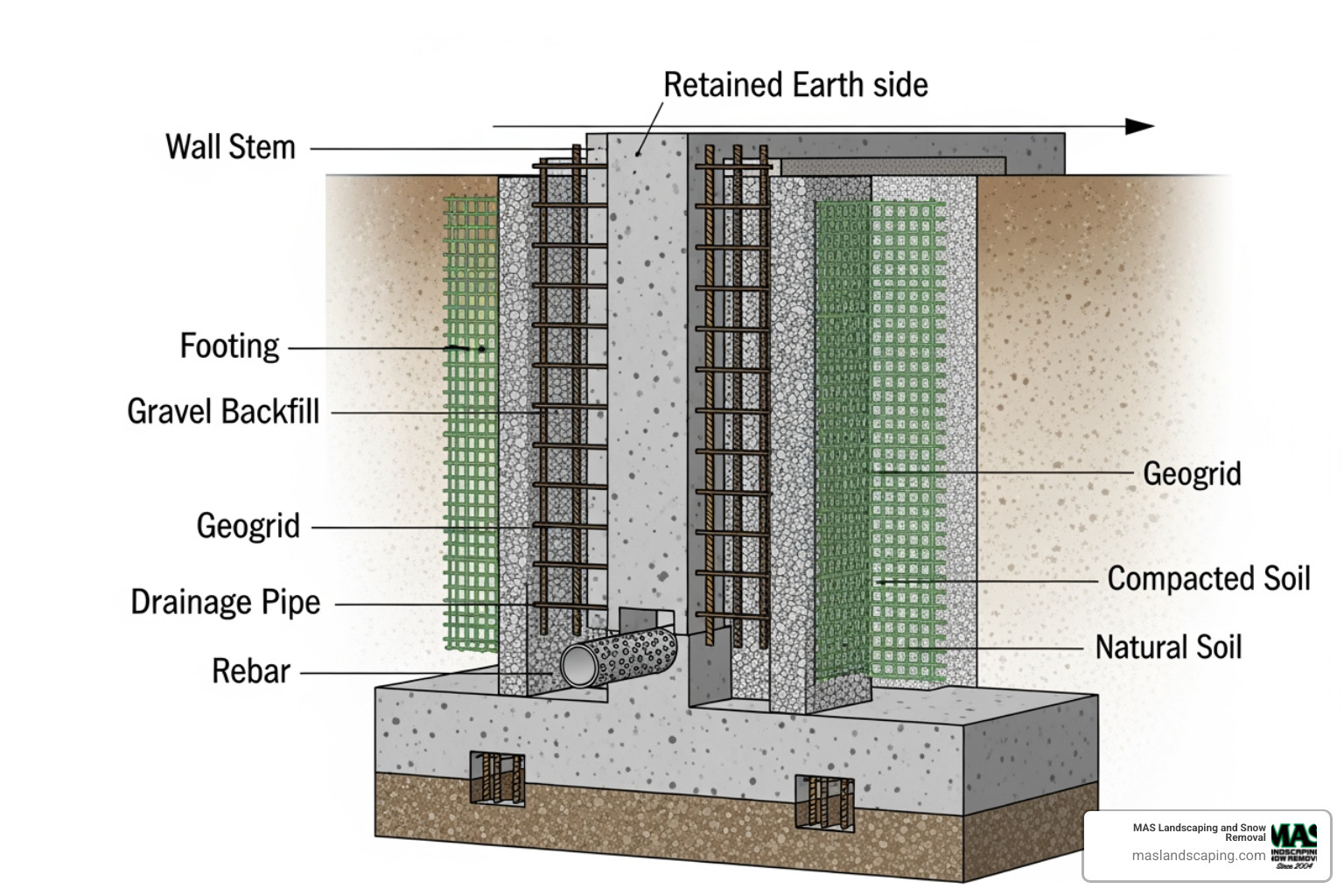

- Wall Stem: This is the most visible part of the retaining wall, the vertical structure that holds back the soil. Its design, whether poured concrete or interlocking blocks, is crucial for resisting lateral earth pressure.

- Concrete Footing: The foundation of the entire wall, the footing is typically wider than the wall stem and buried below ground. It distributes the weight of the wall and the soil it retains over a larger area, preventing settling and providing crucial stability against overturning and sliding. The size of the footing grows depending on the wall’s height and the soil conditions.

- Drainage System: This is arguably the most critical component. Without proper drainage, water accumulates behind the wall, leading to hydrostatic pressure, a leading cause of failure. Our drainage systems typically include:

- Weep Holes: Small openings at the base of the wall that allow accumulated water to escape.

- Perforated Pipe: A pipe installed behind the wall, usually at the base, to collect water and direct it away from the wall. This pipe is often covered with a drain sleeve to prevent clogging.

- Backfill Material: The material immediately behind the wall is vital. We use well-draining materials like crushed stone or gravel, which allow water to flow freely to the drainage pipe, minimizing hydrostatic pressure. This material also reduces the weight directly bearing on the wall compared to dense, water-retaining soil.

- Geogrid Reinforcement: For taller or more heavily loaded walls, geogrid is a geosynthetic material laid horizontally within the backfill. It acts like a tensile reinforcement, tying the wall into the soil mass behind it, significantly enhancing the stability of the backfill and preventing pullout or bulging.

- Wall Cap or Coping: This is the finishing touch on top of the wall. It provides a clean, finished look, protects the wall’s top course from weathering, and can add an aesthetic element to the overall design.

The Unseen Forces at Play

When we design and build a cement retaining wall, we’re not just fighting gravity; we’re contending with several powerful, often unseen, forces:

- Lateral Earth Pressure: This is the horizontal force exerted by the soil behind the wall. It increases with depth, meaning taller walls experience significantly more pressure at their base. The type of soil (e.g., clay vs. sand) and its moisture content heavily influence this pressure.

- Hydrostatic Pressure: As mentioned, water is the arch-nemesis of many retaining walls. When water saturates the soil behind a wall and cannot escape, it creates immense hydrostatic pressure, pushing outwards and downwards. This can cause the wall to lean, crack, or even collapse. This is a common reason why concrete retaining walls may fail.

- Surcharge Loads: These are any additional loads placed on the soil surface above the retaining wall. This could be anything from a patio, a driveway, a building foundation, or even a heavy planter. These loads add to the lateral earth pressure the wall must withstand and must be accounted for in the design.

Understanding these forces is why proper engineering and design considerations are paramount. Compliance with safety standards, such as those outlined in the International Building Code, ensures that retaining walls are built to withstand anticipated loads and environmental conditions, providing safety and reliability. A well-engineered wall, especially in our Massachusetts climate, is built to last.

Types of Concrete Retaining Walls and Their Applications

Choosing the right type of cement retaining wall is crucial for your project’s success. It depends on factors like the wall’s height, the soil conditions, your budget, and the desired aesthetic. We’ll explore the main options available, helping you choose the right fit for your project.

Poured-in-Place Concrete Walls

Poured-in-place concrete walls are constructed on-site by pouring wet concrete into temporary forms. Once the concrete cures, the forms are removed, revealing a seamless, solid wall.

- Characteristics: These walls offer exceptional strength and durability, making them ideal for very tall walls or situations where maximum structural integrity is required. They can be reinforced with rebar for even greater strength. Poured concrete allows for highly customized shapes, curves, and finishes, providing a sleek, modern aesthetic or textured to mimic other materials.

- Applications: We often recommend poured-in-place walls for large commercial projects, significant landscape changes, or when a unique architectural statement is desired. Their robust nature makes them suitable for supporting heavy loads or in areas with challenging soil conditions. While they offer ultimate strength and custom shapes, they generally take longer to install due to the formwork and curing time. If you’re looking for custom wall services that are truly bespoke, this is often the route we take.

Concrete Block & Precast Walls

Concrete block retaining walls, also known as Segmental Retaining Walls (SRWs), are built using individual concrete blocks that interlock. Precast walls use prefabricated concrete panels or large blocks manufactured off-site.

- Characteristics: These systems offer a wide variety of textures, colors, and styles, allowing for significant aesthetic customization. The interlocking design provides stability without the need for mortar between courses (though some systems do use pins or lips for connection). A significant advantage is their faster installation time; precast concrete walls, for example, can reduce project timelines by up to 30% compared to traditional poured-in-place walls. They are also often suitable for DIY projects for smaller, non-structural walls.

- Applications: Concrete block walls are a popular choice for residential landscaping in areas like Saugus, Lynnfield, and Medford, MA. They are excellent for creating garden beds, terracing sloped yards, or building decorative landscape features. For heavy-duty industrial or commercial applications, we might use large interlocking precast blocks like ‘Stack Blok’ or ‘Rock Blok’ systems, which are designed for significant load-bearing. You can learn more about these versatile systems in our Precast Concrete Retaining Wall Guide.

Choosing the Right Type of Cement Retaining Wall

When deciding between poured concrete and concrete blocks, consider this quick comparison:

| Feature | Poured-in-Place Concrete Walls | Concrete Block & Precast Walls |

|---|---|---|

| Installation Speed | Slower (requires formwork and curing) | Faster (blocks are pre-made and interlock) |

| Average Cost | Higher (more labor-intensive, specialized equipment) | Lower (more economical per square foot) |

| DIY-Friendliness | Not recommended for DIY (complex, requires expertise) | Suitable for smaller DIY projects (for walls under 3-4 feet and non-structural applications) |

| Customization | High (any shape, texture, color, integrated features) | Moderate (variety of block styles, colors, and patterns, but shapes are limited by block design) |

While precast walls offer faster installation times, potentially reducing project timelines by up to 30%, poured concrete walls are often chosen when ultimate strength, seamless aesthetics, or highly complex custom shapes are the primary goals.

How to Build a Cement Retaining Wall: A Step-by-Step Guide

Building a cement retaining wall, especially a concrete block wall, can be a rewarding project that significantly improves your property. While we always recommend professional help for walls over 3-4 feet or those supporting significant loads, this guide outlines the fundamental steps involved in constructing a standard block retaining wall.

Step 1: Planning, Permits, and Preparation

This initial phase is critical and can save you a lot of headaches down the line. We can’t stress enough the importance of thorough planning.

- Check Local Building Codes and Permits: This is non-negotiable. In Everett, Lynnfield, Malden, Melrose, Medford, Revere, Saugus, or Chelsea, MA, walls over a certain height (often 3 to 4 feet) typically require a permit and an engineered design. We always ensure compliance with safety standards, such as those outlined in the International Building Code, to guarantee your wall is built to withstand anticipated loads and environmental conditions.

- Mark Your Layout: Use stakes and string to clearly mark the exact location and path of your retaining wall. This helps visualize the project and ensures accuracy during excavation.

- Call 811 Before Digging: Seriously, call 811. Before you put a shovel in the ground, have utility companies mark underground lines to prevent dangerous and costly accidents.

- Calculate Materials Needed: Measure the total length and desired height of your wall. This will help you determine the number of blocks, amount of gravel, and other materials you’ll need. A good rule of thumb is to purchase 10% more material than your estimate to account for cuts or errors.

- Prepare the Site: Clear the area of any vegetation, rocks, or debris. Plan to build when the soil is dry, as this makes excavation and compaction much easier. For more detailed insights, check out our guide on How to Build a Landscaping Wall with Blocks.

Step 2: Excavation and Building a Solid Base

A solid base is the bedrock of any stable retaining wall. Skimping here guarantees future problems.

- Excavate the Trench: Dig a trench for the first course of blocks. The depth should be at least half the height of your first block, plus 3 inches for the paver base. The width should be roughly twice the width of your block to allow for proper backfill and drainage.

- Add and Compact Paver Base: Pour 3 inches of paver base (crushed stone or gravel) into the trench. Using a hand tamper or a vibrating plate compactor, thoroughly compact this material. This creates a dense, stable layer for your first course.

- Create a Level Foundation: This step is crucial. Use a long level (4-6 feet) to ensure the trench is perfectly level lengthwise and a torpedo level to check it from front to back. Adjust with more base material or by scraping away high spots. The first course dictates the levelness of your entire wall! For optimal stability, we typically ensure the base material is consistent with wall rock.

Step 3: Laying the Courses and Installing Drainage

Now comes the fun part: seeing your wall take shape!

- Lay the First Course: Starting at the lowest end of your trench, place the first block, ensuring it’s centered and perfectly level. Tap it gently with a rubber mallet if needed. For low walls, at least half the height of the first course should be below ground level; for walls higher than 3 feet, a full block should be underground.

- Leveling Each Block: As you lay each block in the first course, check it for levelness, both front-to-back and side-to-side. Adjust as necessary.

- Staggering Joints: For subsequent courses, offset the blocks so that the vertical joints are staggered, much like brickwork. This significantly increases the wall’s strength and stability. You’ll often need to cut end blocks in half to start alternating courses, ensuring a consistent pattern.

- Installing a Perforated Drain Pipe: After laying the first course (or two, depending on wall height), install a perforated drain pipe behind the wall. Cover the pipe with a drain sleeve and then with gravel. This system is designed to collect water and prevent hydrostatic pressure.

- Backfilling with Gravel: As you build each course, backfill the space behind the wall with well-draining gravel. Compact the gravel in lifts (6-8 inches at a time) to prevent settling. This gravel layer is essential for directing water to your drainage pipe. This is a critical part of retaining wall installation.

Step 4: Backfilling and Finishing Touches

The final steps involve securing the wall and preparing the area around it.

- Backfilling the Rest of the Wall: Continue laying courses and backfilling with gravel, compacting it thoroughly as you go. Once you reach the desired height, fill the remaining space with topsoil or sod, sloping it away from the wall to encourage surface water runoff.

- Securing Capstones: Brush off any debris from the top course of blocks. Apply a strong construction adhesive to the top of the blocks and carefully place your capstones. These should ideally overhang the retaining blocks by 1 to 1 1/2 inches for a finished look and added protection.

- Final Grading: Ensure the ground around the finished wall is properly graded to direct water away.

By following these steps, you’re not just building a wall; you’re creating a durable, functional, and beautiful addition to your landscape. For integrated designs like a paver patio with retaining wall, these foundational steps are even more crucial.

Cost, Aesthetics, and Common Pitfalls

A cement retaining wall is a significant investment in your property, so understanding the costs, how to make it look great, and what can go wrong is vital. We want you to be fully informed before starting on your project.

What is the Cost of a Cement Retaining Wall?

The cost of a cement retaining wall can vary widely based on several factors, including the type of wall, its height and length, site accessibility, and local labor rates.

Disclaimer: The following cost estimates are average costs based on internet data. Actual costs for MAS Landscaping projects will vary based on specific project requirements, materials chosen, and site conditions. We provide personalized quotes after a thorough consultation.

- Poured Concrete Retaining Wall: The average cost for a poured concrete retaining wall, including materials and labor, typically ranges from $35 to $50 per square foot. However, for complex designs, specialized finishes, or difficult site access, costs can easily reach $100 to $150 per square foot.

- Concrete Block Retaining Wall: Concrete block options are generally more economical, with average costs ranging from $15 to $30 per square foot. For higher-end, decorative blocks or challenging installations, expect costs to potentially rise to $60 to $90 per square foot.

Factors Affecting Price:

- Height and Length: Taller and longer walls require more materials, more extensive excavation, and often more robust foundations and reinforcement.

- Site Accessibility: Difficult-to-access sites in areas like Chelsea or Revere, MA, can increase labor and equipment costs significantly.

- Soil Conditions: Poor or unstable soil may require additional excavation, specialized backfill, or engineered foundations, adding to the overall cost.

- Drainage Requirements: Extensive drainage systems, while essential, will add to material and labor costs.

- Finishes and Aesthetics: Decorative caps, veneers, or special concrete finishes will increase the price per square foot.

For a more detailed breakdown, explore our guide on the Cost of Concrete Retaining Wall.

Common Reasons for Retaining Wall Failure

Nothing is more disheartening than seeing a newly built wall begin to fail. Most failures can be traced back to fundamental errors in design or construction. Understanding these pitfalls is key to avoiding them:

- Poor Drainage (Hydrostatic Pressure): This is, without a doubt, the most common culprit. As we discussed, water accumulating behind the wall creates immense hydrostatic pressure that pushes against the structure, causing it to lean, crack, or collapse. A lack of weep holes, a clogged drain pipe, or insufficient gravel backfill can all lead to this issue.

- Inadequate Foundation: A weak or improperly prepared foundation cannot support the weight of the wall and the retained soil. This can lead to settling, cracking, or the wall shifting out of alignment. The footing must be deep enough, wide enough, and properly compacted.

- Weak or Unsuitable Materials: Using low-quality blocks, insufficient concrete strength, or inadequate reinforcement can compromise the wall’s structural integrity.

- Improper Backfill: Using heavy, clay-rich soil directly behind the wall instead of well-draining gravel or crushed stone will exacerbate hydrostatic pressure issues and add unnecessary weight.

- Overloading the Wall (Surcharge): Placing too much weight (like a new shed, a large planter, or heavy machinery) too close to the top of the wall without accounting for it in the design can cause it to fail prematurely.

Building a durable hardscape retaining wall requires attention to these details.

Enhancing Your Concrete Block Wall’s Appearance

While concrete blocks are incredibly functional, their appearance might not always align with your desired aesthetic. Fortunately, there are many ways to improve a cement retaining wall to perfectly complement your landscape design.

- Stucco or Parging: Parging involves applying a thin coat of cementitious mortar to the wall’s surface, creating a smooth, finished look. This can cost, on average, $1.50 – $3.50 per square foot. Decorative stucco coverings, which offer a wider range of colors and textures, typically cost $3.00 – $4.00 per square foot. Stucco also minimizes heat transfer and protects the blocks from weather.

- Artificial Stone Veneer: For the look of natural stone without the higher cost and complexity, artificial stone panels (veneers) are an excellent option. They come in various designs, like river rock or slate, and can be applied directly to the concrete blocks. The cost for artificial stone veneer typically ranges from $13.00 – $30.00 per square foot. This is a less costly, easier way to achieve the look of a natural stone appearance.

- Painting the Wall: After parging, painting the wall is an economical way to add color and blend it with your landscape. This usually costs around $0.65 – $0.80 per square foot. Ensure you use a quality concrete primer before painting.

- Natural Stone: For a truly rustic and high-end look, natural stone can be mortared onto the concrete block wall. While more expensive, it offers best beauty and durability.

- Natural Green Covering: Climbing plants like ivy or clematis can soften the hard lines of a concrete wall, adding natural color and texture. However, it’s crucial to apply a cement barrier before planting to prevent damage to the concrete block.

Combining these aesthetic improvements with thoughtful landscaping ideas for retaining walls can transform a utilitarian structure into a stunning focal point.

Frequently Asked Questions about Cement Retaining Walls

We often hear similar questions from homeowners in Saugus, Everett, and surrounding Massachusetts towns. Here are answers to some of the most common inquiries about cement retaining walls.

How long does a concrete retaining wall last?

A well-constructed cement retaining wall can exceed 50 years. Its longevity is directly tied to several factors: proper design that accounts for soil pressure and drainage, a solid and adequately prepared foundation, the quality of materials used, and effective drainage systems to prevent water pressure buildup. When built correctly, these walls are truly built to last for generations.

Do I need a permit to build a retaining wall?

Permit requirements for retaining walls vary significantly by municipality. In our service areas like Lynnfield, Malden, Melrose, and Medford, MA, it is generally required to obtain a permit for walls over 3 to 4 feet in height. Walls exceeding this height often necessitate an engineered design to ensure structural integrity and safety. It is absolutely crucial to check with your local building department before starting any construction project to understand their specific regulations and avoid potential penalties or the need to tear down your work.

Can I build a retaining wall on a steep slope?

Yes, retaining walls are specifically designed for managing slopes. For very steep inclines, a series of shorter, terraced walls is often a safer, more effective, and more aesthetically pleasing solution than attempting to build one very tall wall. Terracing distributes the load more effectively and creates usable, level areas within the slope. For any significant slope or large-scale project, professional consultation and an engineered design are highly recommended to ensure stability and prevent failure. Our team has extensive experience with building a retaining wall on a slope cost and construction.

Conclusion: Building with Confidence

A cement retaining wall is more than just a barrier against soil; it’s a long-term investment in the safety, functionality, and beauty of your property. As we’ve explored, the recipe for a lasting wall hinges on three critical takeaways: meticulous planning, a robust foundation, and an effective drainage system. These elements are non-negotiable for ensuring your wall stands strong against the forces of nature, especially in the varied climates of Massachusetts.

While small, decorative walls in your garden might be a rewarding DIY project, larger, structural walls—those over a few feet tall or supporting significant loads—demand professional expertise. The complexities of soil mechanics, hydrostatic pressure, and proper engineering require a seasoned hand to ensure safety and longevity. Cutting corners on these essential aspects can lead to costly failures down the line.

At MAS Landscaping, we pride ourselves on our local expertise in the Saugus, MA, area and surrounding communities like Everett, Lynnfield, and Chelsea. We understand the unique soil conditions and weather patterns of our region, allowing us to design and install cement retaining walls that are not only beautiful but also built to last.

For professional guidance and installation of your hardscape project, explore our Retaining Wall Installation services. Let us help you transform your landscape with confidence, block by block.